Internal Collection System And Conveyance Network

Here are 674 registered member units spread in an area of 13.5 sq. km. in Vatva GIDC Estate. The effluent from every member unit is conveyed through Internal collection system (ICS) consisting of 95 sump rooms-with 5-9 member unit connections and 7 pumping stations. All the member units have to follow the CETP inlet norms given by GPCB as below, only after that they have to send their effluent to CETP.

All the member units have to provide over head tank and discharge their preliminary treated effluent from their overhead tank through above ground pipeline to the respective sumps. Between the overhead tank and sump room, members have to provide strainer, valve and sampling point. From the sump room, wastewater flows under gravity to the pumping station from where the effluent is pumped to collection tank of CETP.

Treatment Process of CETP

Primary Treatment

A collection cum screening tank is the first course in effluent treatment which receives preliminary treated effluent as an inlet of CETP. The condensate from MEE and spray dryer are also pumped to collection tank. The treated effluent from Novel is also sent to GESCSL CETP for further treatment. From the collection tank the wastewater is flash mixed where coagulants and flocculants are mixed. The cationic and anionic coagulants are added through dosing pump from the chemical tanks and are thoroughly mixed in the Flash mixer.

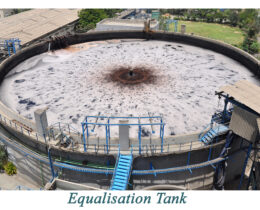

After complete mixing of the coagulants like Cationic and Anionic polyelectrolytes with the effluent, the effluent is clarified in clarifloculator with designed detention time of 3.45 hrs. The solids separated during clarification are collected in primary sludge holding tank from where it is pumped to centrifuge decanter for dewatering. The dewatered sludge is then transported to TSDF and the concentrate from decanter is transferred to equalization tank. The supernatant flows to equalization tank for homogenization. The equalization tank provides a detention time of 24.87 hrs under designed flow. In equalization tank the content is thoroughly mixed with the help of course bubble diffuser aeration supported by Turbo Aerator.

The equalized flow is sent to flash mixer where cationic polyelectrolyte and anionic polyelectrolyte are added. After complete mixing of the chemicals with effluent, it flows into flocculator tank where coagulation and flocculation of suspended solids, colloids and dissolved pollutants takes place. The overflow from flocculator goes to settling tank and flocs removed by scrapper in the form of sludge. DAF unit works on the principle of super saturation of the liquid with dissolved air. However, under the present circumstances, the functionality of DAF is in-effective and the unit is used just as a settling tank.

Secondary Biological Treatment Activated Sludge Process

The extended aeration model is employed for biological treatment. The effluent received from settling tank where the desired level of DO and MLSS is provided by five numbers of root blowers (each of 175 HP capacity) with medium bubble diffused aeration grid and 23 nos. triton type Jet Aerators (each of 60 HP capacity) with 10 HP air blowers.

The treated sewage from STP, Vinzol (Municipal Corporation) is added to aeration tank for bio augmentation. The organic matter and some nutrients in the form of nitrogen and phosphorous present in wastewater are degraded aerobically by the active micro-organisms contained in the activated sludge.

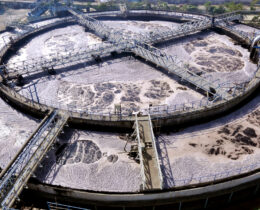

Two secondary clarifiers having a total capacity of 3924 m3 (each of 1962 m3 capacity) receive an effluent containing MLSS through the flow distribution chamber. Anionic poly-electrolyte & spent aluminium chloride (75 ppm) are aided to the effluents from aeration tank before clarification in the secondary clarifier. The spent aluminium chloride which is used as chemical aid for clarification is a by-product of CETP member units viz. M/s. Meghmani Organics and M/s Ami Organics Industries. The activated sludge mixed liquor is clarified by gravity in the clarifiers from where it is taken to the Sludge Sump.

A portion of this activated sludge (Recycled Activated Sludge) is recycled into the aeration tank to maintain F/M ratio. The excess sludge (Waste Activated Sludge) is taken into sludge holding tank from where it is pumped to Centrifuge/Decanter for dewatering. Again non-anionic polyelectrolytes are added to decanter. The supernatant/treated effluent from the secondary clarifiers is collected in Holding Tank from where it is pumped to river Sabarmati for discharge through a closed Mega pipeline. The treated effluent is pumped to mega line which carries effluent of reliance 11 and other CETP like Naroda, Odhav, Narol Dyestuff for ultimate discharge at downstream of river Sabarmati where it is mixed with 1000 MLD treated Sewage.

Sludge Treatment and Disposal

The sludge from primary and secondary tanks is collected in sludge holding tanks from where it is pumped to centrifuge decanter dewatering. The dewatered sludge is transferred to Storage facility and then disposed off to GPCB authorized TSDF site. The Centrate from decanter is transferred to Equalization Tank. Leachate from sludge storage facility is also transferred to Equalization tank for treatment. The dewatered solids are sent to GPCB authorised TSDF site Previously, the sludge was sent to Secured Landfill Disposal facility at Vinzol village developed by GESCSL; however this site has been exhausted since 2013.